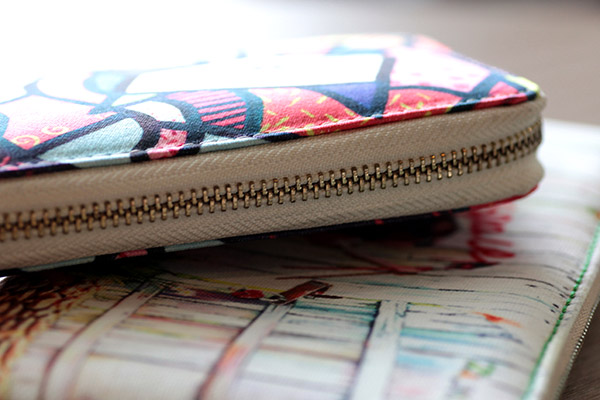

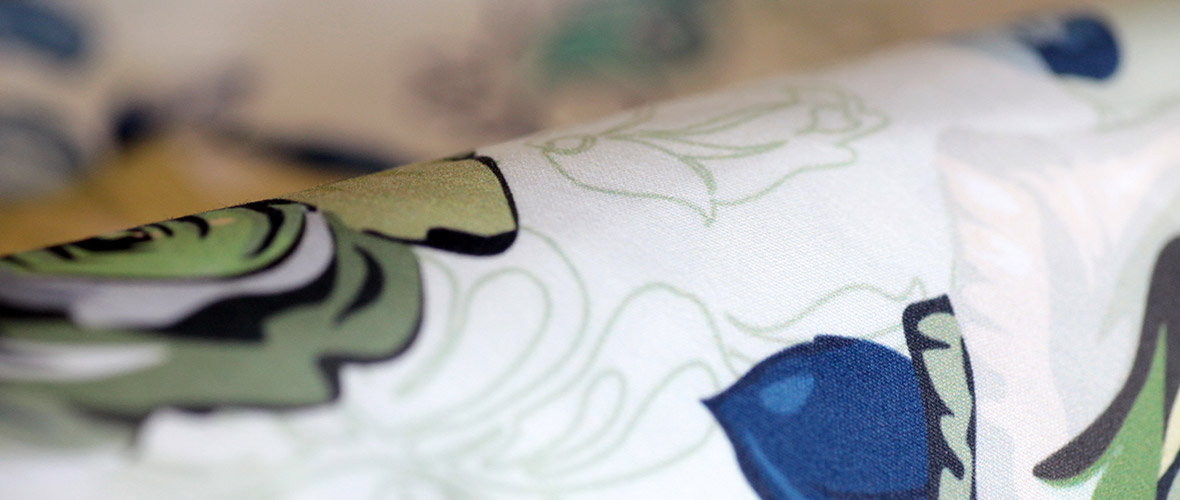

Textile Pigment ink

Features

- Bright color

- High color fastness, dry and wet friction resistance, water washing resistance.

- The finished product feels soft and prints smoothly.

- Complying with OEKC-EX100 standard.

Color

Print media & Applicationse

Pure Cotton

Canvas

Blended Fiber

Linen

Processing technology

Precoating the fabric

Pretreatment can optimize the performance of textile ink. After sizing, the fabric can obtain higher fixing effect and consistency of printing effect, It greatly simplifies the printing process.

Direct printing to garments

New direct pigment ink for pure cotton can be used for personalized printing on various clothing garments. No limit to size, no limit to color, it meets the diverse needs of the market.

Drying fixation

It only needs 90 seconds of warm dry at 120 degrees Celsius to fix the color. The gas produced during the warm dry is water vapor. After printing, the fabric need to be hot-pressed (to improve the color fastness of the ink, fixing methods vary according to the composition of the fabric)

Textile Pigment ink color fastness

| Color Fastness To Washing |

4 - 5 | |

| Color Fastness To Rubbing | Dry Staining | 5 |

| Wet Staining | 4 - 5 | |

| Color Fastness To Perspiration | 4 - 5 | |

| Color Fastness To Light | 7 - 8 | |

| * SGS Test data (AATCC) | ||

Apply for print heads

| Type | For use |

|---|---|

| Epson | DX5/DX7/TFP/5113/4720/V540/TX800/XP600 |

| Industrial print head |

|